Message In A Bag

Ideas and the process, according to the fundamental principles of Apple, is a product of those who are round pegs in square holes, and those who see things differently and, most times, the bulb glows when one least expects it.

"I was watching a documentary," said Tricia Williamson, social media and online communications manager, Jamaica Public Service (JPS), "I saw how, in Africa, they used material from billboards to make bags, and I thought, why we can't do the same here?"

The light-emitting diodes (LED) of the television screen transmitted the inspiration and the BannaBags project was conceived.

The objective was two-pronged,Williamson said, to reuse and recycle banners and billboards, which

would have found their way into the dump, and to provide a cheap and sturdy option for school children.

"This project is addressing a viable need and helping schoolchildren who are in need of

back-to-school supplies, at the same time providing employment for those who are associated with producing these bags," Williamson added.

JPS has collaborated with HEART Trust/NTA GARMEX Academy for the production of BannaBags. The material and designs are supplied by JPS and the bags are manufactured by the institution.

PERSONAL TOUCH

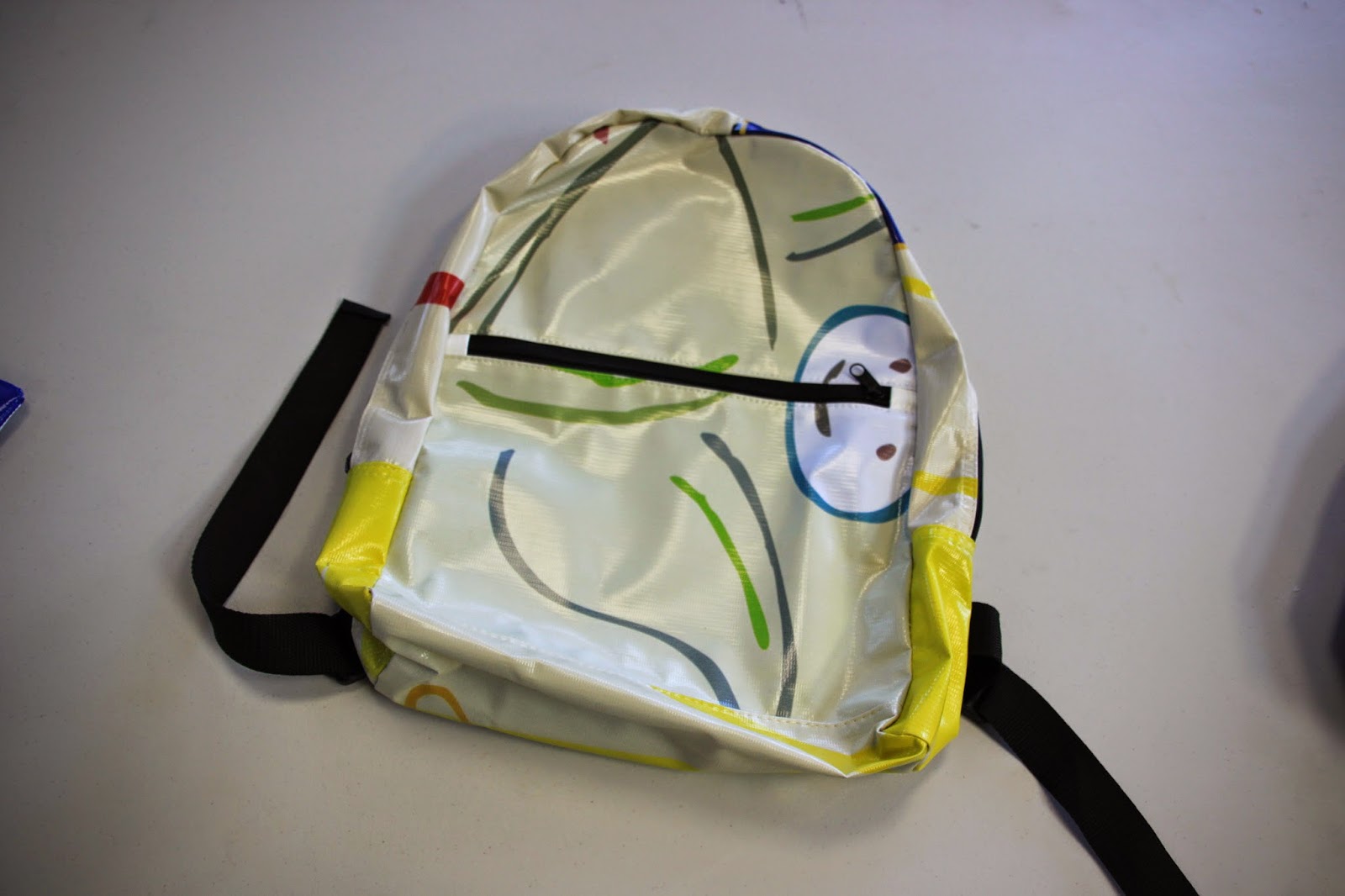

The bright, psychedelic bag with abstract designs is a synergy of the materials and messages used.

"No two bags are the same, which gives that personal touch for the user," said Shenee

Tabannah, communications officer at JPS.

From ideation to the final merchandise, BannaBags go through a series of processes. "Initially, the biggest challenge was to get the raw material, but as the word spread, more companies (started) coming on board," Williamson informed.

At the GARMEX factory, Clive Walcott, holds an electric-powered cutter moving it over a stack

of vinyl with the same ease that one would run knife through butter, this is the intermediate process as the advertising banners are transformed.

"We have to inspect the banners that come to us," informed Rita Palmer, deputy manager at HEART Trust/NTA GARMEX Academy.

"Some (banners) might not be suitable as they are very thick, while others are either dirty or worn

out."

Once the vinyl is ready to be processed, it is spread and the design of the various parts of the bag are marked on them.

The vinyl is then spread and cut, around 13 plies at a time. The cut vinyl is then sent to the sewing department,where the wadding and the lining are cut separately, and all the material is converged, assembled and sewn.

"The whole process can take around an hour," Palmer said.

"We are happy for this opportunity," said Arden Grant, principal director HEART Trust/NTA, "we are using what would have been thrown out.

"Importantly," she added, "we are able to provide employment to our trainees, who are exposed to the real world of work. They can produce similar products once they have experience."

Now in Phase 2, BannaBags project aims to reach a wide spectrum of students across Jamaica, with support from corporate groups.

"It is gratifying," Williamson said.

Messages, it is said are omnipotent and omnipresent, and after they have lived their lifecycle in high-traffic thoroughfares, they are now being spread across the smiles of scores of school children across the island.

Comments

Post a Comment